The first

large-scale CO capture plant will probably be a post combustion process based

on amine absorption, or an oxyfuel process.

But as we

look ahead to 2030 and onwards, new and improved concepts for CO2 capture will

become available. Technologies listed below are currently in various stages of

development and expected to become commercially available in the coming

decades.

Looking ahead to 2030

The

introduction of new technologies always starts with promising prototypes that

are heavily improved as time goes by. This evolutionary improvement is also

expected to be the case with CO2 capture technology.

Consider

the mobile phone. The first prototypes twenty years ago were large, bulky and

expensive. Few people could imagine that this was the beginning of a

development that would alter how people across the globe communicate and

conduct commerce. Today there are more than 5 billion mobile phones, many

affordable to people in the most disadvantaged nations.

A similar

development of CO2 capture technology can also be expected. The first

large-scale CO2 capture plants will probably be based on post-combustion amine

absorption. Soon after oxyfuel and pre-combustion plants will follow.

All these

first-of-its-kind CO2 capture plants will be more capital intensive and less

efficient then subsequent generations. As greater numbers of CO2 capture plants

are installed cost will reduce due to greater operational knowledge and a

refinement of the technologies.

But if we

look ahead to 2030 and onwards there are likely be new alternatives that become

cost-effective offering greater efficiency gains. Some of these future

alternatives include membranes, chemical looping and adsorption (not

absorption!).

Membrane

Membranes

can be used for separating CO2 from other gas components. The technology is

available today but will take some years and further research before it may be

available for large-scale CO2 capture at generation plant.

The

concept is simple. Similar to a filter, components which diffuse more readily

through a material under pressure may be separated out. Generally CO2 capture

membranes are designed to be selective for smaller gasses, for example allowing

Nitrogen to pass through while leaving a pure stream of CO2 behind. Existing

membrane technology currently available does not provide the CO2 purity

necessary for transport. It is possible to increase purity with multi stage

membranes but this also substantially increases the energy penalty required for

repeated compression.

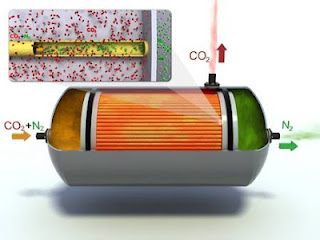

A coal

power plant emits large volumes of CO2 and will consequently require large

areas of membrane. The membrane unit must be small and compact to keep the cost

down. In the figure above this is solved by manufacturing the membrane as thin

hollow fibres. Thousands of such membrane fibres are then combined into a

membrane module in order to obtain a high membrane area within a small volume.

In an

ideal membrane, a high selectivity for the chosen gas will be achieved at low

pressures and low energy costs. With regard to CO2 capture, current research

focus on overcoming challenges related to the material design and improving

membrane performance. Furthermore, energy is required to force gases through

the membrane, and the thicker membrane, the more energy is needed. It is a challenge

to produce membranes as thin as possible to reduce the energy requirements.

Chemical looping

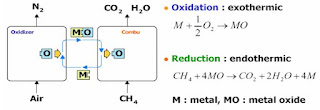

Chemical

looping is a new technology for combustion with inherent CO2 capture. It is a

significant departure from traditional combustion methods. It is flameless

combustion technology combining two reactors, one air reactor and one fuel

reactor.

In the

air reactor oxygen from the air reacts with a metal-based material to form a

metal-oxide and heat. This metal-oxide becomes an oxygen carrier and is

transferred to the fuel reactor where it reacts with a fossil fuel. The

reaction consumes some heat while producing CO2, water and regenerating the

metal to a pure state. The metal is then recycled to the air reactor and the

cycle repeated.

The

beauty of this process is that it has many of the advantages as oxyfuel, but it

solves the challenges related to oxyfuel. Oxyfuel has the advantage of having a simple and

cheap CO2 separation process, but a challenge is to produce cheap and pure

oxygen. Similar to oxyfuel chemical looping produces a relatively pure stream

of CO2 and water vapour which can be readily separated by a traditional

condensing process.

A major challenge

is the development of robust and efficient oxygen carrier particles. The

reactants must be highly reactive, thermodynamically stable while resistant to

deactivation and degradation. Metal-based materials for reacting with oxygen

and the fuel are currently under development. At present the development of

chemical looping technology is in the early stages and significant development

is needed to commercialise the technology.

Integrated fuel cells

Integrated

fuel cells enable production of the clean energy carriers electricity and

hydrogen from fossil fuel or bio-fuel with ultra-high efficiency and integrated

CO2 capture.

As an

example a process developed by ZEG

Power is described in the following sub-section.

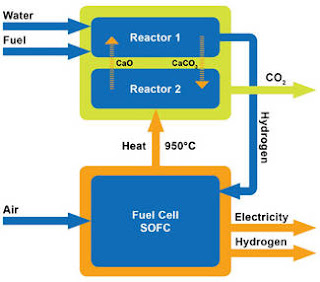

The

electricity is produced from a Solid Oxide Fuel Cell (SOFC) module. The

SOFC module converts fuel to electricity electrochemically without any

conventional combustion. The efficiency of the SOFC module is in the 50% to 70%

range, depending on the operating conditions (ZEG

Power).

Combining

a SOFC with a hydrogen reformer for co-production of electricity and hydrogen

makes a system with a theoretical efficiency of 100%. CO2 capture is enabled

without theoretical energy losses, but some energy losses due to the operation

is however inevitable in real processes. CO2 capture processes require energy,

usually in the form of heat. In an amine process as well as in the ZEG process,

heat is required to release CO2. The same amount of heat is released while the

CO2 is absorbed, but at a lower temperature. When this heat is taken from a

heat powered system, the CO2 capture will reduce the overall efficiency of the

system. In the ZEG process the heat is released at a temperature that is high

enough for the hydrogen reformer, and the waste heat from the CO2 capture

process can be fully utilised in the reformer.

This

particular process also eliminates the need for an afterburner, usually

required in SOFC systems. It further improves the operating conditions for the

SOFC, resulting in higher efficiency and/or lower costs for the SOFC module.

The process completely eliminates the need for combustion, and NOx emissions

are virtually zero. The challenge is to prove the design for larger

(>200Mwh) plants.

Adsorption

As

previously mentioned, the first large-scale CO2 capture plants will probably be

based on post-combustion absorption. But a future alternative to absorption is

adsorption.

During

CO2 capture by absorption a liquid chemical, called solvent, will react with

the CO2, while in adsorption the CO2 will be attached to the surface of a solid

component, called sorbent.

Pressure

swing adsorbtion is a process that utilises the different solubility’s of

gaseous components in a solid. At high pressure, CO2 is adsorbed onto a porous

materials, when the pressure is decreased the gas is desorbed from the porous

sorbent producing a pure CO2 stream. The sorbent can be reused for subsequent

adsorption as the chambers continue to oscillate between high and low pressure

selectively to adsorb and desorb CO2.

The

challenges for adsorption are similar to those related to absorption; finding

new sorbents that react more efficiently and faster with CO2 and that require

less energy to be regenerated. The development of regenerable sorbents that

have high selectivity for CO2 is critical for the adoption of the pressure

swing adsorption process.

CO2

capture by adsorption is not yet a mature commercial technology, but is

currently being tested at a laboratory scale. Research programs are underway

with advances in the technological expected, paving the way for adsorption as a

future solution for CO2 capture.

Source:

BELLONAENVIRONMENTAL

0 comments:

Post a Comment